Stanhope had its beginning as a small, forge town in the late 18th Century and developed into a substantial iron-manufacturing community in the 19th Century. The major outlet for goods into upper Sussex County was through the Morris Canal which flows through the center of the community. At the early part of the 20th Century, the iron complex had enlarged many times and was under the control of the Singer Manufacturing Company of Elizabeth, New Jersey. Although the iron manufacturing period of Stanhope was concluded around 1925, numerous remnants of the early industrial community have survived. Between 1930 and 1980 the Borough's population grew, more than tripling in size, even though a portion of Stanhope split off to join Byram Township during this period. The construction of summer homes was found to spring up along the countryside, many of which were converted to year-round houses.

Stanhope's history is routed in the production of iron. The Musconetcong River which runs along the edge of the town made the location a favorable one for iron manufacture. In addition to the source of water power, several other vital ingredients were close at hand. Great quantities of iron ore were available at the nearby Stanhope or Hude Mine (near present-day Pennyton Homes), at the Roseville Mines in Byram Township, and in Morris County at the Dickerson Mine on Mine Hill. Wood supply, which was essential for producing charcoal to fire the early forges and furnaces, was also conveniently nearby. The early iron companies at Stanhope owned large tracts of forested land and included all of present-day Stanhope, Netcong, Port Morris, parts of Byram Township, as well as at least a dozen iron mines in surrounding Morris, Sussex and Warren Counties. One final necessary ingredient, limestone, was also within close proximity. Andover and its surrounding areas had considerable limestone deposits that yielded the all-important flux required for separating the iron from the impurities in the ore. For all of the above reasons, it was not surprising that early iron concerns were attracted to Stanhope.

The earliest records indicate that the first iron production at Stanhope occurred about 1794. The Dickersons, a very prominent family from Morris County, were the founders of this early industry. Silas Dickerson, brother of the future state governor and U. S. Senator Mahlon Dickerson, erected the first forge and nail factory on the Musconetcong River in Stanhope. The nail factory was one of the earliest in the state. By about 1800, another forge, a gristmill and a sawmill, were erected in town, just a little further downstream. As is the case with most early New Jersey iron manufacturing enterprises, the Stanhope iron companies alternately prospered and faced financial reverses until about 1830 when the wood supply for charcoal was exhausted and the works were forced to shut down. It was at this time that the Morris Canal was completed through the center of Stanhope and across northern New Jersey. A link was thus opened to a new type of fuel, Pennsylvania anthracite coal. Now the failing iron economy of New Jersey could be revitalized.

The opening of interstate highways and better transportation arrangements brought an influx of people, making Stanhope itself a suburb of the older cities to the east. In this period of latest growth, citizens have become more and more aware that development should not continue into the Borough's areas of greater natural constraint without regulation and restriction. The Borough has begun to tighten up and plan for its future. Building, zoning, health and other ordinances have been enacted and enforced. The records of the governing body itself have been moved from informal storage arrangements in each official's home to the old firehouse and finally to the present municipal building.

By 1841 the Stanhope Iron Company had acquired the iron works' tract of land in Stanhope and had erected three anthracite blast furnaces at an expenditure of about $75,000. These early furnaces represent the first successful use of anthracite coal for firing blast furnaces in the State of New Jersey and the sixth such use in the United States.

The Stanhope Iron Company had originally incorporated as the Morris and Sussex Manufacturing Company in 1835 to produce cotton, wood, iron and window sashes. By 1841 the concern changed its name to the Stanhope Iron Company and focused its attention on iron manufacture.

By 1845 the corporation was again reorganized, this time to be known as the Sussex Iron Company. Edwin Post, a New York capitalist, became the head of the iron complex and operated a highly-successful concern. Some of Post's iron, which was produced from franklinite ore, was tested at the French National Establishment for the Manufacture of Chains and Anchors for the Navy. The iron "...was found to possess an absolute tenacity exceeding that of any iron ever tried. The iron and steel made from it, said to possess superior qualities for cutlery and other uses, commanded a higher price than any other" (Bishop, 1868).

In 1845 a major agreement between the Sussex Iron Company and the Morris Canal and Banking Company redistributed the water rights to the Musconetcong River. Previously, the two companies had competed for water rights, one to operate an iron industrial complex and the other a canal. The agreement transferred most of the water rights to the canal company which was at that time authorized to construct a reservoir, present Lake Musconetcong, at Stanhope. In return the canal company had to guarantee sufficient water to the Sussex Iron Company to operate its grist mill and blast furnaces. It also was to pay $12,000. to the iron company for the construction of a steam engine at the furnace. Finally, the canal company was to construct a branch canal which would extend from the main canal at the head of Plane No. 2 West at Stanhope to the furnace site. The new waterway would allow iron ore boats to dock adjacent to the iron complex.

In 1853 one of Post's experiments using franklinite ore to produce both iron and zinc resulted in a devastating explosion at the furnace. This accident and other financial reverses resulted in the end of the active operation of the Sussex Iron Company. In 1864 the Musconetcong Iron Works, incorporated by a group of New York capitalists, acquired the iron works complex at Stanhope. A total rebuilding and enlargement program was begun. In 1869 A. Pardee and Company of Philadelphia gained control of the company and continued these renovations. The works operated from the 1860's until 1902 when the Singer Manufacturing Company of Elizabeth, New Jersey purchased the entire corporate stock of the Musconetcong Iron Works.

Iron manufactured by the Stanhope furnaces was transported via the Morris Canal and the Delaware, Lackawanna & Western Railroad to areas of northern New Jersey and various other states including New York and Pennsylvania. By 1881 annual production of the Musconetcong Iron Works had reached 40,000 tons of pig iron. Considerable quantities of this iron were shipped to Paterson to supply the extensive machine manufacturing complexes of this large New Jersey industrial center.

The Singer Manufacturing Company of Elizabeth operated the iron complex in Stanhope as one of its foundries from 1902 until 1925. A large poured concrete structure was erected at the site in 1908, one of the early examples of this type of construction. This building, which straddles the Musconetcong River, is the only extant [still in existence] structure of the furnace complex proper. The rest of the structures were demolished in 1926, but even a quick survey indicates that extensive archeological evidence of the complex remains. A massive 25-30' high stone retaining wall still stands adjacent to where the old furnaces were situated. A series of brick and stone wall remnants are apparent above the wall as are the large slag dumps (waste created by the furnace operation). Evidence of the forge and furnace hydropower systems remain apparent at the artificially created furnace pond. A beautiful, cut stone arched bridge, erected in 1875, stands at the outlet of the pond. The old branch from the Morris Canal, which enabled ore boats to travel to the furnace, remains largely intact with its sluice gates and spillway. Ruins of ore docks are apparent at its terminus.

Directly across from the furnace site stands the U. S. Mineral Wool Company, still functioning since 1875. This plant, one of the first of its kind in the country, was erected opposite the old furnace in order to manufacture slag wool for insulation. The operation was interrelated with the furnace process since the waste from the furnace was used to produce the insulating material. All of the structures from the Mineral Wool Plant have been replaced by more up-to-date facilities.

The old Stanhope furnace office is still standing and is used as the company office for Salmon Brothers Inc., contractors. It has recently been altered, although the chemical storage vault still remains adjacent to the main structure.

Over the years, the iron complex in Stanhope evolved to include a variety of other industries and businesses that were necessary to accommodate the growing community. These buildings were owned by the iron company but were usually operated by tenants. Included were a tannery, two grist mills, sawmills, a plaster mill and a blacksmith shop. Several stores were operated in town, the majority of which were depots that served the Morris Canal. Many of the above structures are described in the Historic Stanhope Tour Guide, published by the Musconetcong Foundrymen Historical Society in 1980.

Another all-important ingredient to an iron company town was tenant housing, homes for the furnace laborers. Stanhope has dozens of these dwellings, which remain to illustrate the evolution of housing from the early double family tenant housing of about 1820 to the multiple family dwellings of about the 1880's. The housing even includes the iron master's or supervisor's house, a very impressive brick home indicative of the owner's social standing in the community.

Examples of several other early town institutions in an iron community survive. These include the Stanhope Presbyterian Church, which was erected in 1844 on a plot of land donated by the iron company; the old 1855 Stanhope School, also erected on iron company land; and two tavern-hotel buildings, one of which dates back to about 1800.

Stanhope certainly owes a good deal of its early importance to the fact that it was located on a major transportation route. By 1810 or earlier, the Morris & Sussex Turnpike was completed through the center of the community. The roadway linked Stanhope to a series of towns to the east including Elizabeth, the Oranges, Madison, Chatham, Morristown, and Succasunna. To the north the turnpike provided access to Newton, the county seat. Early hotel-stage coach stops were erected to service the travelers who came through Stanhope, the gateway to Sussex County. One of these structures, the Stanhope House, remains standing. Present-day Main Street follows the old route of the turnpike through the heart of the community.

An even more important transportation link that extended through Stanhope was the Morris Canal. The Morris Canal & Banking Company was incorporated in 1824 to construct a navigable waterway across northern New Jersey. Designed to link Phillipsburg with Newark and Jersey City, the canal was conceived as the answer to revitalizing New Jersey's depressed iron economy, which had exhausted charcoal supplies. By connecting the Pennsylvania coal fields with the iron manufacturers of northwest New Jersey, the machinery manufacturers of Paterson and Newark, and finally the market of New York City, the canal would provide great impetus to the New Jersey economy.

Completed in 1831 from Phillipsburg to Newark, the Morris Canal had to climb 914 feet to its summit at Lake Hopatcong and then descend 760 feet to the Delaware River at Phillipsburg. This incredible mountain-climbing canal had 32 locks and 23 incline planes (railroad tracks which ran up or down an incline plane and connected sections of the canal at the top and bottom of a hill). A long, continuous cable, operating on a drum and a series of pulleys, pulled a cradle car with the canal boat resting in it either up or down the hill. The whole mechanism was powered by a waterwheel and was capable of lifting the 70-ton boats. The canal boats, which were 10 feet wide and 70 feet long, were built in two sections and hinged in the middle. This allowed the boats to bend as they passed over the summits of the incline planes. The Morris Canal continued to operate until 1924, although business had declined for many years. The slow, mule-towed vessels could not compete with the railroads. By 1929 the canal had been dismantled.

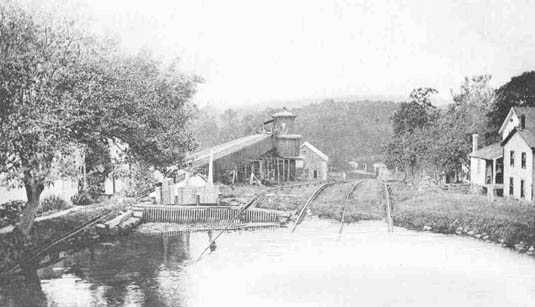

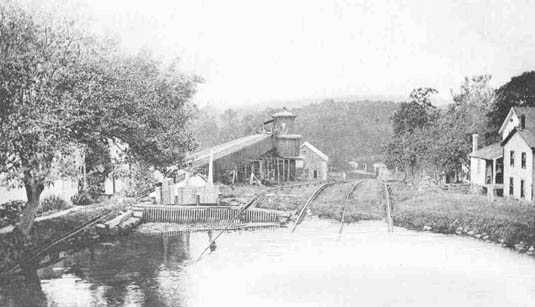

The canal in Stanhope crossed Lake Musconetcong, paralleled Main Street, and descended Plane No. 2 West at the far side of town. Depots built on the banks of the canal handled merchandise and transformed Stanhope into the major outlet for canal goods shipped into upper Sussex County. Today extensive remains of the canal in Stanhope are apparent. The canal proper is on the National Register of Historic Places, but many interrelated sites and structures in Stanhope have been overlooked. These include canal section superintendents' houses, boatmen's houses, and small industries that shipped their goods on the canal and used its water as a power source.

The next major transportation system to affect Stanhope was the Morris and Essex Railroad, built in about 1853. Although the main tracks and station were located in Netcong, on the Morris County side of the Musconetcong River, a siding was extended to the iron works, thus forming an excellent means of delivering the pig iron that was produced there.